By Jessica Parnham

Head of Marketing and Content Strategy

Last week, the BBC reported that a UK legal claim involving more than 3,000 people has been filed against Johnson & Johnson, alleging prior knowledge and failure to warn about asbestos contamination in its historic talc-based baby powder products. Public concerns centre on the possible presence of asbestos fibres and their established link to serious diseases, such as mesothelioma and other cancers. The case, which follows years of similar litigation overseas, has raised an important question: how could an ingredient used in so many everyday products become contaminated by one of the world’s most dangerous fibres?

In this article, we explore the science behind asbestos contamination in talc, tracing its geological origins, the ways contamination can persist through mining and processing, and the regulatory frameworks designed to detect and prevent it.

The Geological Overlap Between Talc and Asbestos

The potential for asbestos contamination in talc products begins far beneath the ground. Talc and asbestos are both naturally occurring minerals that form under similar geological conditions. They are often found within the same metamorphic rock formations, meaning that veins of asbestiform minerals such as tremolite or anthophyllite can lie adjacent to or intermixed with talc deposits.

When talc ore is mined, it is therefore possible for trace amounts of these fibrous minerals to be extracted at the same time — particularly if the boundaries between deposits are not precisely defined. Even with modern geological mapping, this overlap can be difficult to predict, making geological co-location the root cause of potential contamination.

In short, asbestos is not an ingredient in talc, but a naturally associated impurity that must be identified and excluded through rigorous testing and quality control.

How Asbestos Contamination in Talc Can Happen

Once mined, talc ore undergoes crushing, milling, and refinement before it becomes the fine powder recognised and used in a range of everyday products. At each of these stages, there are opportunities for cross-contamination if strict segregation and housekeeping are not maintained.

During mechanical processing, any fibrous minerals present in the ore can fragment and become airborne. Without appropriate dust controls or purification systems, these fibres may remain within the product stream. Similarly, when talc from several sources is blended to standardise texture or colour, this process can unintentionally distribute low-level contamination throughout larger batches.

Understanding how these processes create opportunities for contamination is only part of the picture. Determining whether asbestos fibres are actually present and in what quantity relies on the sensitivity and accuracy of laboratory analysis. However, detecting trace asbestos in talc is a highly complex challenge.

The Challenge of Identifying Asbestos Fibres in Talc

The challenge of detecting asbestos contamination in talc lies in identifying extremely small quantities of asbestos fibres within a mineral that is chemically and visually similar.

Earlier testing techniques, such as X-ray diffraction, infrared spectroscopy and polarised-light microscopy, were originally developed to analyse bulk mineral samples. These methods were effective for identifying major mineral components but often lacked the sensitivity to detect very fine fibres or extremely low concentrations of asbestos. As a result, trace contamination could go undetected or be misclassified.

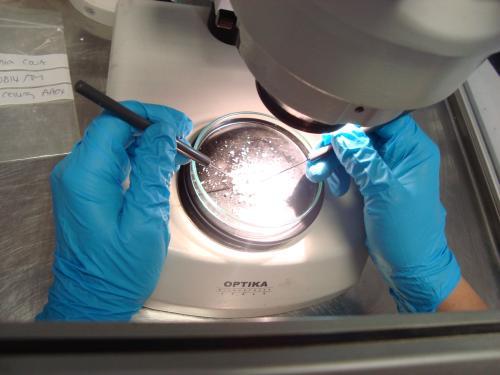

Advances in microscopy have transformed this field. Modern laboratories now rely on high-resolution transmission electron microscopy (TEM), often supported by complementary analytical tools such as energy-dispersive X-ray spectroscopy (EDS) and selected-area electron diffraction (SAED). These techniques allow scientists to examine materials at the nanometre scale, confirming both the crystal structure and chemical composition of any fibres present.

Within the UK, TEM-based analysis represents the benchmark for asbestos detection in UKAS-accredited laboratories, including those overseen by the Health and Safety Executive (HSE). However, even with these advances, identifying asbestos at very low levels remains technically demanding. Variability in sampling size, sample composition, and the statistical limits of fibre counting all influence results. For this reason, regulators place increasing emphasis not only on test outcomes, but also on the robustness of the analytical method and the laboratory quality assurance that underpins it.

The UK Regulatory Landscape

The UK’s regulatory framework for asbestos and product safety is built on this same principle of methodological rigour. Under UK Cosmetics Regulation, which is derived from retained EU law, manufacturers are required to ensure that any cosmetic product placed on the market is safe under normal or reasonably foreseeable use. For talc-based products, this means verifying that the mineral is asbestos-free through rigorous testing and supply-chain due diligence.

Reputable manufacturers now source talc from geologically verified deposits and commission independent laboratory analysis using high-resolution electron microscopy. These steps align with the UK’s overarching approach to asbestos management, which prioritises traceability, transparency, and evidence-based verification.

Beyond the cosmetics sector, the Health and Safety Executive (HSE) and the Office for Product Safety and Standards (OPSS) conduct ongoing market surveillance programmes to test talc-containing products available to UK consumers. Results to date show that asbestos contamination is rare, though isolated detections have led to further investigation and, where necessary, product recall.

Internationally, regulatory agencies such as the U.S. Food and Drug Administration (FDA) are moving toward stricter, standardised asbestos testing requirements for talc-containing cosmetics — developments that may shape the direction of UK policy in the future.

Why Contamination Risk Persists

Despite the progress made through modern testing and regulation, asbestos contamination in talc remains a matter of serious concern. The geological overlap between talc and asbestos is a natural occurrence that cannot be engineered away, meaning the potential for trace contamination will always exist. Even at extremely low concentrations, asbestos fibres pose significant health risks, and their presence in any consumer product warrants careful investigation.

The global nature of the talc industry adds further complexity. Talc is mined in many parts of the world, including regions where regulatory standards, mine auditing, and laboratory testing requirements differ significantly from those applied in the UK or EU. In such cases, variations in ore characterisation, sampling practices, or quality assurance can increase the likelihood that contaminated material enters international trade. Reports from past decades have highlighted issues in talc exported from certain regions of Asia, Africa and South America, where geological mapping and asbestos control measures were less stringent.

Within the UK, the combination of source auditing, laboratory verification, and regulatory oversight significantly reduces this risk — but does not erase it entirely. The recent UK legal claim against Johnson & Johnson underscores that the issue remains both real and consequential, serving as a reminder that continued vigilance, transparent reporting, and consistent international regulation are essential to protect public health.

How Envirochem Can Help

As a UKAS-accredited laboratory and consultancy specialising in asbestos monitoring, surveying, and occupational hygiene, Envirochem supports organisations in understanding, managing, and mitigating asbestos risk in all forms.

Our experts work across both industrial and environmental sectors, advising clients on compliance with Control of Asbestos Regulations 2012, designing air monitoring programmes, conducting bulk sample analysis, and ensuring that asbestos exposure risks are correctly assessed and documented.

We also maintain close awareness of emerging regulatory developments and testing methodologies, ensuring our clients stay informed of evolving standards whether they relate to construction, occupational exposure, or wider product safety. Through this expertise, Envirochem continues to provide the technical insight and assurance that businesses need to navigate complex regulatory landscapes with confidence.

For more information about our UKAS-accredited asbestos services, visit our Asbestos Services page or get in touch with one of our experts today.

Author

Related Content

How can we help?

Contact UsWebsite Privacy Policy - Privacy Notice - Terms & Conditions

© Envirochem Analytical Laboratories Ltd

Reg. No. 2378228 England